What Cable Is Correct for Your Application?

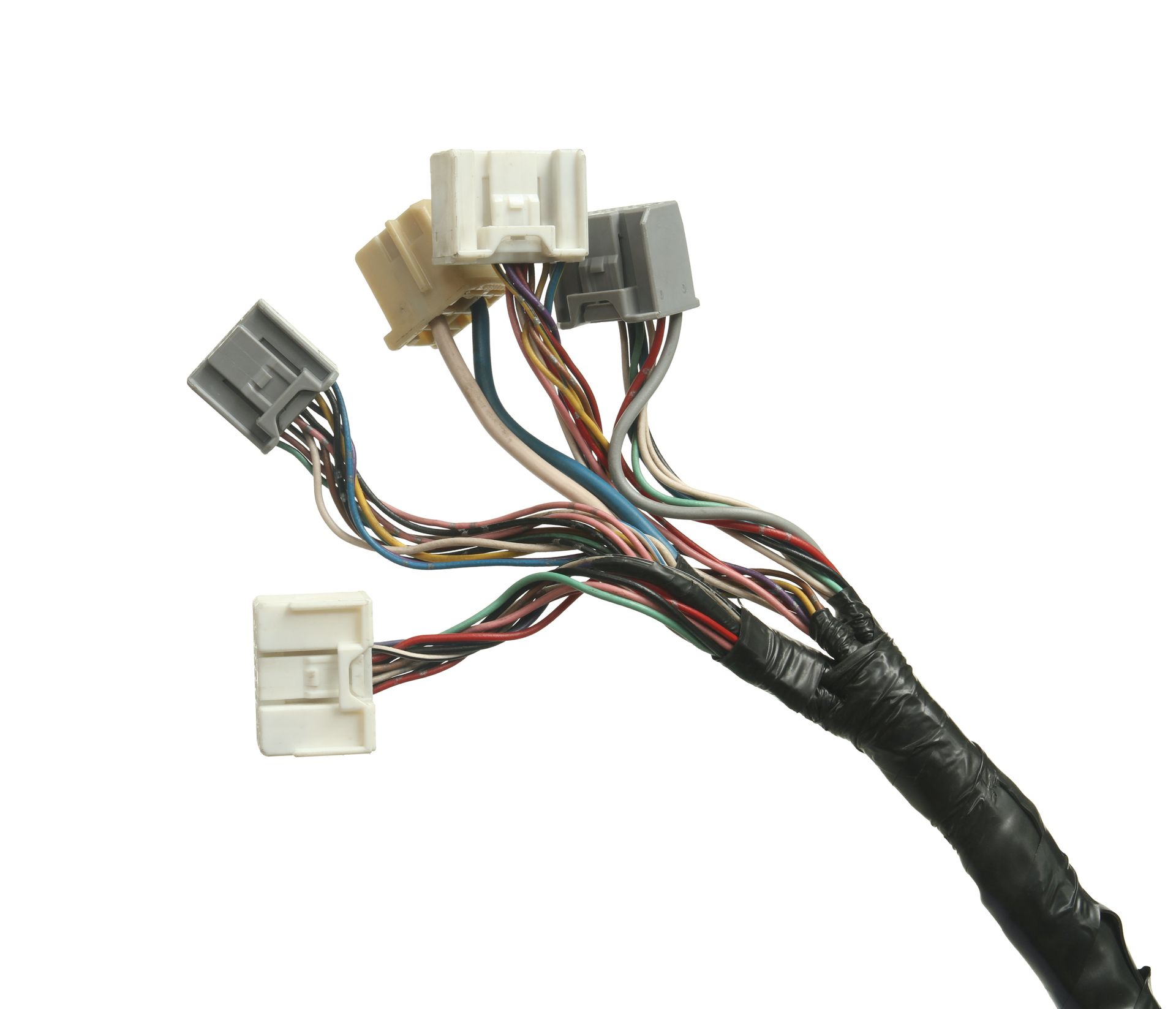

At RPI, we recognize the critical responsibility of selecting the appropriate cable for your wire harness application. With our wide variety of cables, each offering unique features and benefits, we ensure that you find the perfect fit. In this article, we will delve into the factors to consider when choosing a cable, including gauge, length, insulation, environmental factors, and cost. By understanding these aspects, you can make informed decisions that result in reliable and efficient wire harnesses.

Gauge - Determining Current Carrying Capacity

The gauge of the wire plays a vital role in determining its current carrying capacity. Thicker wires with lower gauge numbers can handle higher current loads. For instance, a 12-gauge wire can carry up to 20 amps, while a 14-gauge wire is limited to 10 amps. Understanding the current requirements of your application ensures optimal performance and prevents potential electrical issues.

Length - Accounting for Voltage Drop

The length of the wire directly impacts its resistance and can lead to voltage drops over longer distances. It is crucial to select a wire length that adequately spans the connection points while minimizing resistance. For example, when connecting components that are 10 feet apart, choose a wire length of at least 10 feet to mitigate voltage drop and maintain consistent power delivery.

Insulation - Protecting Against Hazards

The insulation on the wire provides protection against electrical shock and safeguards against short circuits. Selecting the appropriate insulation material depends on the environmental conditions in which the wire will operate. If the wire is exposed to water, it should have water-resistant insulation. Considering the specific environmental factors ensures durability and longevity of the wire harness.

Environmental Factors - Adapting to Conditions

Environmental factors such as temperature extremes, exposure to chemicals, and vibrations can influence the cable's performance. Choosing cables engineered to withstand these conditions guarantees reliability and longevity in challenging environments. It is crucial to assess the operating conditions to select cables that can endure the demands of the application.

Cost - Balancing Quality and Budget

The cost of the cable depends on various factors, including the type, gauge, length, and insulation. Thicker wires with advanced insulation tend to be more expensive. Balancing the cable's cost with its performance and the requirements of your application ensures a cost-effective solution without compromising on quality or reliability.

Choosing the Right Wire

To make an informed decision when selecting cables for your wire harness, consider the factors discussed above. If you are unsure about the most suitable cable for your application, consult with our experts. Their experience and knowledge will guide you in selecting the ideal cable that aligns with your needs and budget.

Additional Tips Regarding Cable Selection:

- Consult with an expert: Seek advice from industry experts to ensure you choose the most suitable cable for your application.

- Read the manufacturer's specifications: Thoroughly review the manufacturer's specifications to ensure the chosen cable can handle the required voltage and current.

- Use the correct tools: Employing the right tools for working with wire ensures proper installation and minimizes the risk of damage to the cable and connectors.

- Test the connections: After installing the cable, perform thorough tests to validate the connections and verify their proper functioning.

Choosing the proper cable for your custom wire harness application is essential for achieving reliable and efficient electrical connections. By carefully considering gauge, length, insulation, environmental factors, and cost, you can make informed decisions that result in robust and durable wire harnesses. Our team at RPI is ready to assist you in selecting the ideal cable that meets your specific requirements. Contact us today to find the perfect cable for your custom wire harness needs.

Proudly Manufactured in the United States

At RPI, we take great pride in manufacturing custom wiring harnesses that are made right here in the US. From our base in Racine, Wisconsin, we use only the highest quality materials and components to craft wiring solutions that are durable, reliable, and built to last. By choosing RPI, you can trust that you are getting a product that is not only tailored to your specific needs, but also represents the quality and craftsmanship of American manufacturing.

Upload Your Design

Build Spec Review of your Design Guided by a Dedicated Program Manager

Design Review by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

Start Your Design

Design and Development Process with a Dedicated Program Manager

Design Drawings performed by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

More Recent Insights

Quick Links

Get in Touch

Footer Contact Form

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | RPI Manufacturing