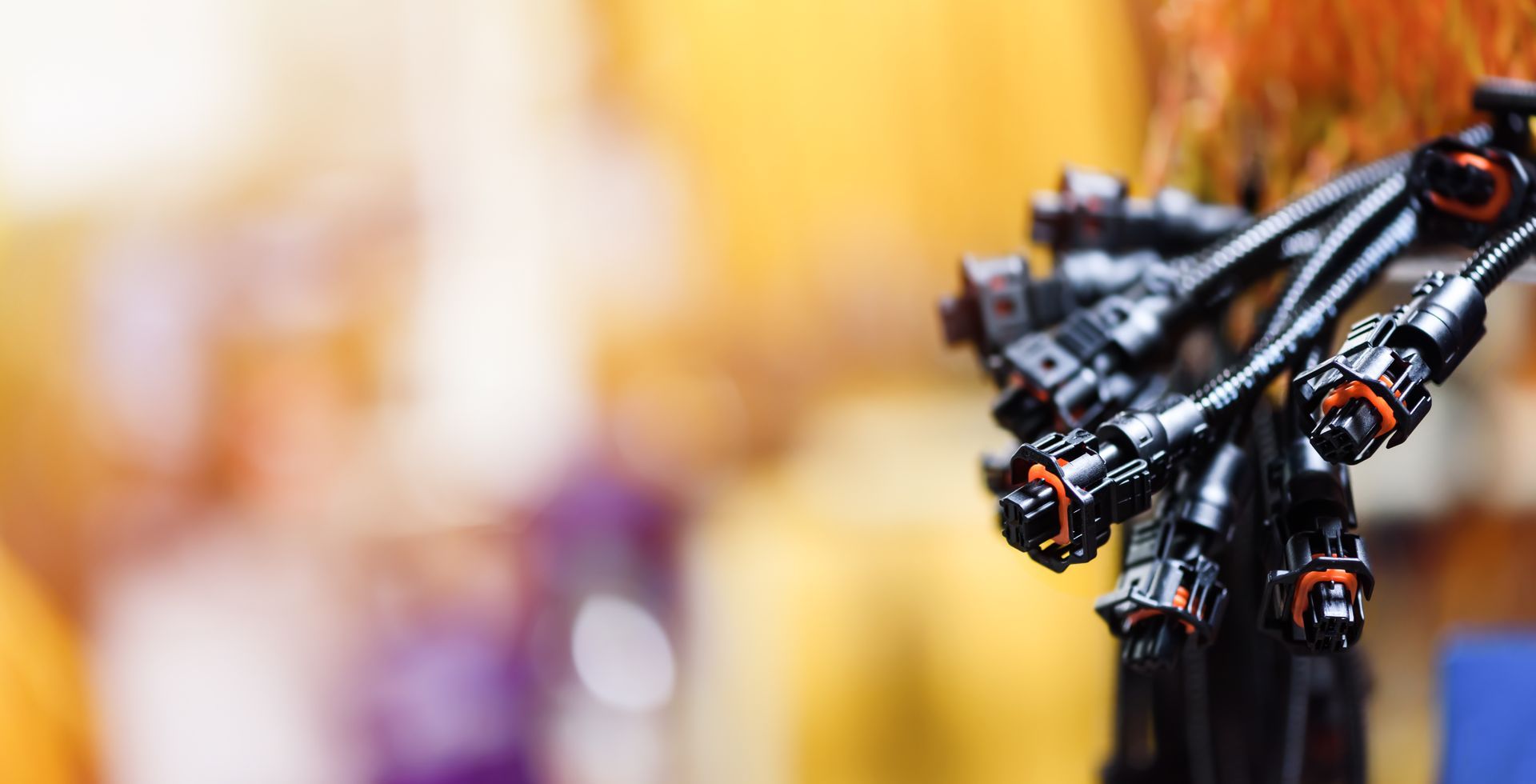

The Nation's Premier Commercial Wire Harness Manufacturers

From automotive and aerospace to industrial and medical, we have the expertise and experience to design and build custom wire harnesses and PCB's that meet your exact specifications. RPI is ISO 9001-2015 certified.

Upload Your Design

Build Spec Review of your Design Guided by a Dedicated Program Manager

Design Review by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

Start Your Design

Design and Development Process with a Dedicated Program Manager

Design Drawings performed by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

Why Choose Us?

Industry Expertise

With years of experience in these fields, we bring unmatched expertise to every project. Our team of skilled professionals understands the unique requirements of a myriad of industries, delivering solutions that exceed expectations.

Customized Solutions

We don't believe in one-size-fits-all solutions. Whether you need a complex wiring system for your next-generation vehicle or a high-performance harness for aerospace applications, we tailor our services to meet your specific needs and requirements.

Cutting-Edge Technology

We invest in the latest technology and tools to stay ahead of the curve. From advanced design software to a state-of-the-art production facility, we leverage cutting-edge technology to deliver precision-engineered wire harnesses of the highest quality.

Scalability

Whether you need a small batch or a large-scale production run, we have the capacity and capability to handle orders of any size. Our streamlined processes and efficient production methods ensure timely delivery without compromising on quality.

Quality Assurance

Quality is at the core of everything we do. Our rigorous quality control measures and testing protocols ensure that every wire harness meets the highest standards of performance, reliability, and durability.

We specialize in serving national brands and large manufacturers in verticals from automotive, agricultural, factory automation, aerospace, and more, delivering top-notch quality and expertise for your production needs. Join the ranks of leading manufacturers who trust us for their wire harness needs, and experience the difference first hand. Contact us today to discuss your project requirements and discover how we can help you achieve success.

Proudly Manufactured in the

United States

At RPI, we take great pride in manufacturing custom products that are made right here in the US. From our base in Racine, Wisconsin, we use only the highest quality materials and components to craft wiring solutions that are durable, reliable, and built to last. By choosing RPI, you can trust that you are getting a product that is not only tailored to your specific needs, but also represents the quality and craftsmanship of American manufacturing.

Commercial Wire Harness and cable Products

Point to Point Harnesses

Point to Point Harnesses are designed to provide accurate and reliable wiring connections in a minimal amount of space. Our experienced team of engineers can design and manufacture harnesses to meet the most demanding specifications and to ensure optimal electrical performance.

With RPI's Point to Point Harnesses, you can trust that your equipment will operate at peak efficiency and productivity, while minimizing the risk of electrical failures and downtime.

Multiple Branch Conductor

Multiple Branch Conductors provide an effective solution for the distribution of power and control signals to multiple locations in industrial and automation settings. Our custom-designed harnesses can be tailored to meet your specific requirements, ensuring that your equipment operates with maximum efficiency and productivity.

With RPI's Multiple Branch Conductors, you can trust that your power and control signals will be distributed accurately and reliably, helping to prevent costly downtime and delays in production.

Commercial Wire Harness and cable Creation for Industry Specific Solutions

Latest Insights

What Clients Say About Us

Rather Connect Over the Phone or Chat?

Looking for a more personalized experience? We've got you covered! Whether you prefer the ease and convenience of a phone call or the flexibility of chat, we're here to connect with you on your terms. Our friendly and knowledgeable team is always available to answer your questions, discuss your needs, and provide tailored solutions that meet your specific requirements. So why wait? Contact us today and let's connect on your preferred platform!